NS Kn Series Kneaders are custom-built to match a variety of compounds according to customers’ needs. Our Kneaders Are Built For Mastication, Master Batch And Final Batch Production. Our Rotors Are Specially Designed & Developed In House Ensures Perfect Mixing And Dispersion Of Carbon & Chemicals.

We Encourage Customer To Use Our Kneaders For Both Masters And Final Batches. Where Water Cooled Rotors, Chamber & Floating Lid Ensure Adequate Cooling Effect. Variable Frequency Drives Control Rotor Speed As Per Compound & Stage Of Mixing.

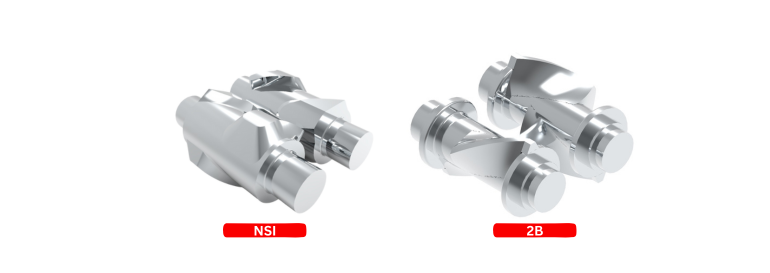

Improved Compound Quality Is Achievable With Our New Generation NSi- Series Intermeshing and Tangential Rotors. All The Parts In Chambers Which Will Play A Vital Role In Mixing Operations Are Protected Special Coating For Tougher Applications Like Silica & Other Additives. With Special Spring Type Dust Seals Will Ensure Zero Compound Leakage.

Why choose NS Kn-Series Kneaders

1- Single piece Rotors to ensure no water leakage

2- Full Body Stellited Rotors

3- Empowered With NS-Tangential Rotors Antifriction Bearings

4- Empowered With NSi – Series Intermeshing Rotors Antifriction Bearings

5- Ram Positioning Control System Along With Variable Pressure & Variable Ram Speed

6- Shorter Batch Cycle & Higher Fill Factor Ensuring Higher Productivity

7- Chamber Assembly with complete water circulation

8- Heavy Duty Fabricated Base with vibromounts

9- Spring Loaded Dust Seal Assembly

10- Feeding Door with sliding safety cover

11- IoT Enabled / Industry 4.0 Product

| NS Kn Series Kneader (@35 RPM) | |||||||

|---|---|---|---|---|---|---|---|

| Model No. | KnL | Kn1 | Kn2 | Kn3 | Kn4 | Kn5 | Kn6 |

| Volume (In Liters) | 3 & 5 | 25 | 35 | 55 | 75 | 110 | 150 |

| Suitable Mill size | - | 14” x 36” | 16” x 42” | 22” x 60” | 24” x 72” | 26” x 84” | 30” x 100” |