Rubber processing is a critical aspect of the tyre and technical rubber industries. Whether you are producing automotive components, industrial seals, or high-performance tyres, the efficiency and reliability of your rubber mixing process can make a significant impact on your final product. One of the most vital pieces of machinery in this process is the rubber mixing mill.

Understanding the Rubber Mixing Mill

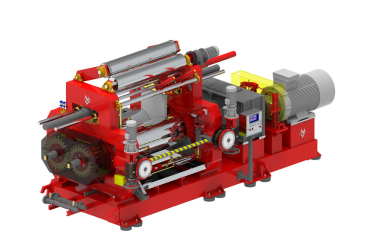

A rubber mixing mill is a specialized machine designed to blend raw rubber with various ingredients to achieve the desired properties for different applications. It consists of two rotating rolls that work together to mix, refine, and homogenize rubber compounds. The effectiveness of this machine directly influences the quality, consistency, and durability of the final rubber product.

As a crucial piece of equipment, choosing the right rubber mixing mill is essential. With several rubber mixing mill manufacturers available in the market, selecting the best one requires a careful evaluation of various factors, including durability, efficiency, and technological advancements.

Key Features to Consider in a Rubber Mixing Mill

When investing in a rubber mixing mill, businesses should consider several important factors:

1- Durability and Build Quality – A high-quality rubber mixing mill should be made of robust materials to withstand heavy-duty industrial applications. Look for machines with strong steel frames and high-grade alloy rolls to ensure longevity.

2- Precision and Efficiency – An efficient rubber mixing mill should offer precise control over temperature and mixing time. Advanced models come with automated control systems that ensure consistency and uniformity in mixing, which is crucial for product quality.

3- Customization Options – Different rubber compounds require different processing techniques. The ability to customize the speed, pressure, and roll gap can significantly enhance the effectiveness of the rubber mixing mill.

4- Ease of Maintenance – Regular maintenance is necessary to keep the machine running smoothly. Opt for a rubber mixing mill machine manufacturer in India that provides reliable service support and easy-to-replace parts.

Why Choose a Reliable Rubber Mixing Mill Manufacturer?

Selecting a reputable manufacturer ensures that your investment in a rubber mixing mill yields long-term benefits. Reliable rubber mixing mill manufacturers offer advanced technology, precision engineering, and after-sales service, which are critical for smooth operations.

NS Mixing Group is one such trusted name in the industry. Established in 2015, we have steadily grown into a leading brand recognized for our cutting-edge technology and exceptional service. Our extensive network of clients spans the Middle East, Africa, Southeast Asia, and the Indian subcontinent, making us a preferred choice for businesses seeking top-tier rubber processing solutions.

Conclusion

In the competitive rubber industry, having the right equipment is key to success. A high-quality rubber mixing mill ensures efficiency, consistency, and improved product quality. When looking for a trusted rubber mixing mill machine manufacturer in India, NS Mixing Group stands out as a leader, offering innovative and reliable solutions tailored to your needs. With over a decade of experience serving the tyre and technical rubber industries, we take pride in delivering world-class products backed by exceptional service and support.

For more details on our premium rubber mixing mills, visit NS Mixing Group today and take your rubber processing operations to the next level.